The folder of the project can be fount here

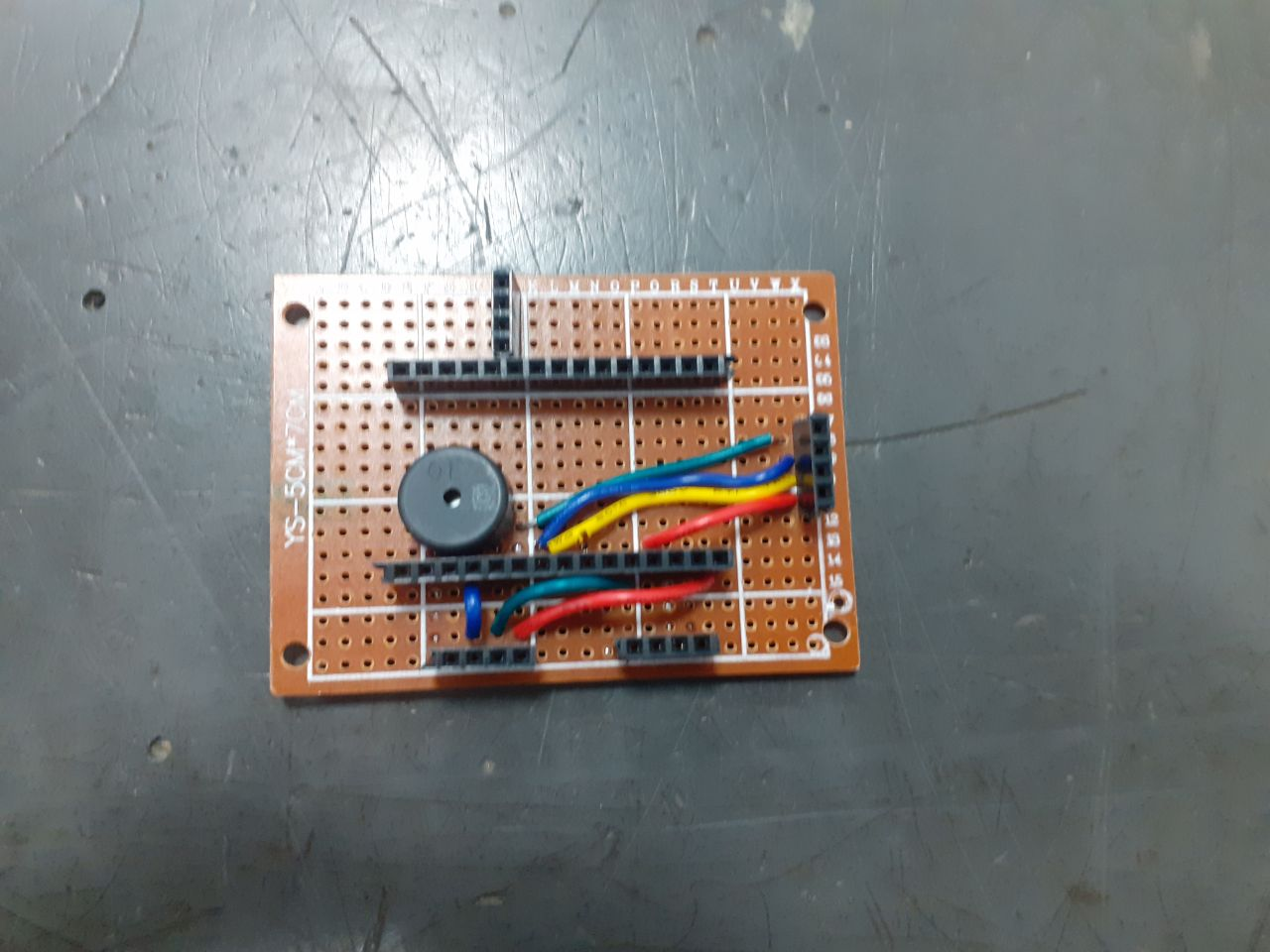

Task Part 3 Compact electronics

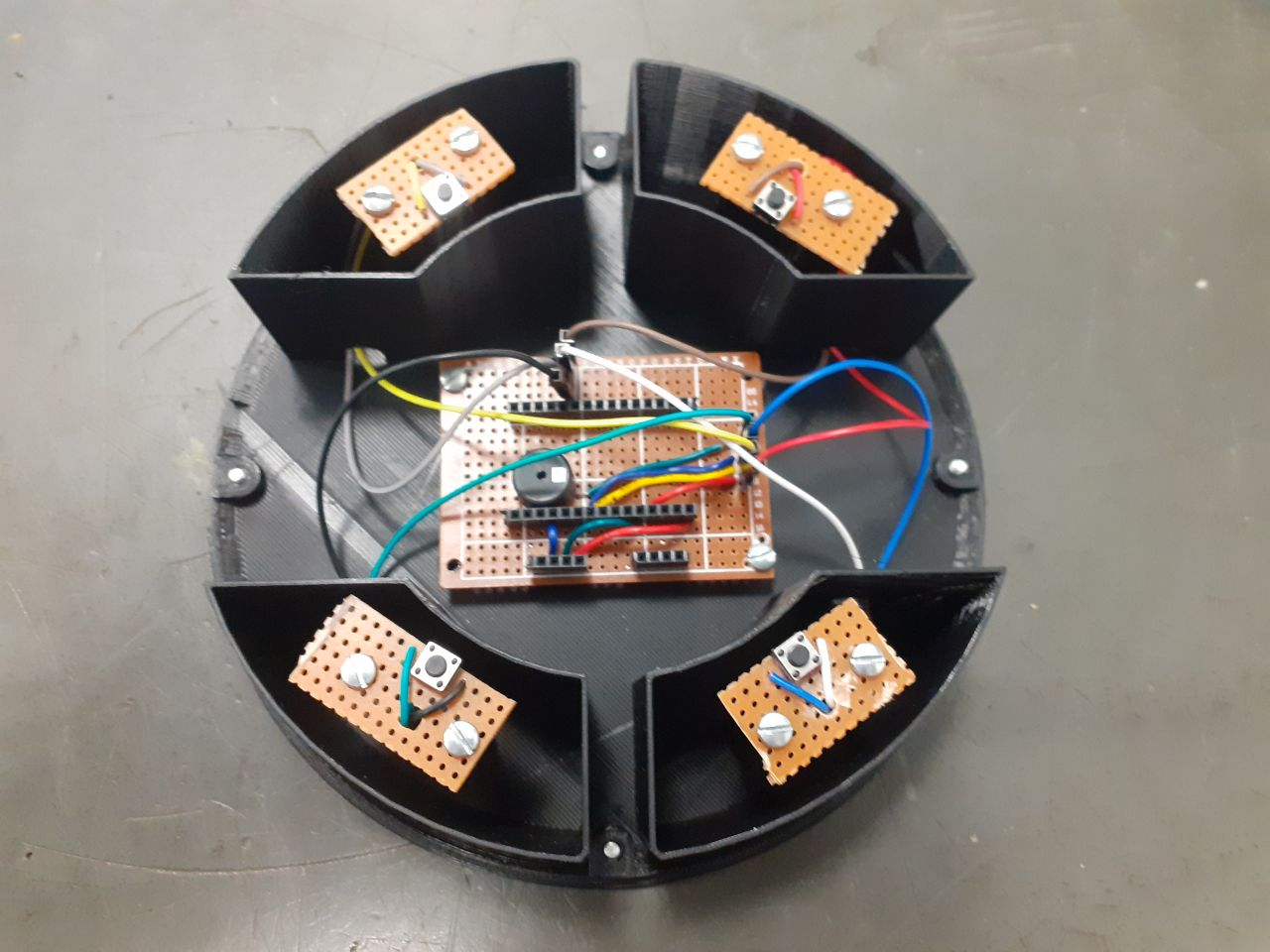

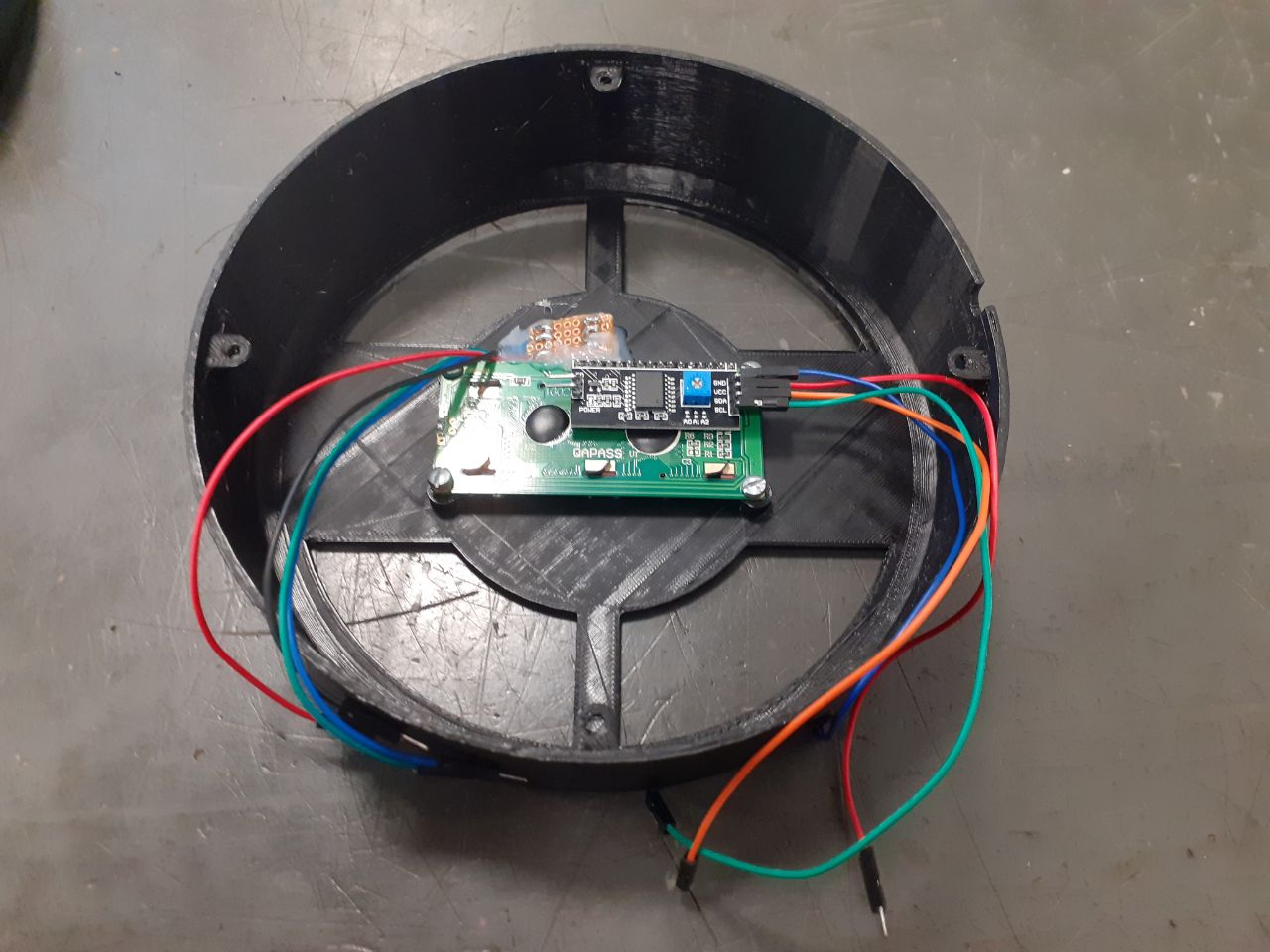

The electronics have been soldered to a soldering board, this way the prototype is robust and also it is compact. The buttons are in separed soldering board because we will put them near the 3D printed buttons. The different parts are built with female and male pins making it possible to replace some part if necessary.

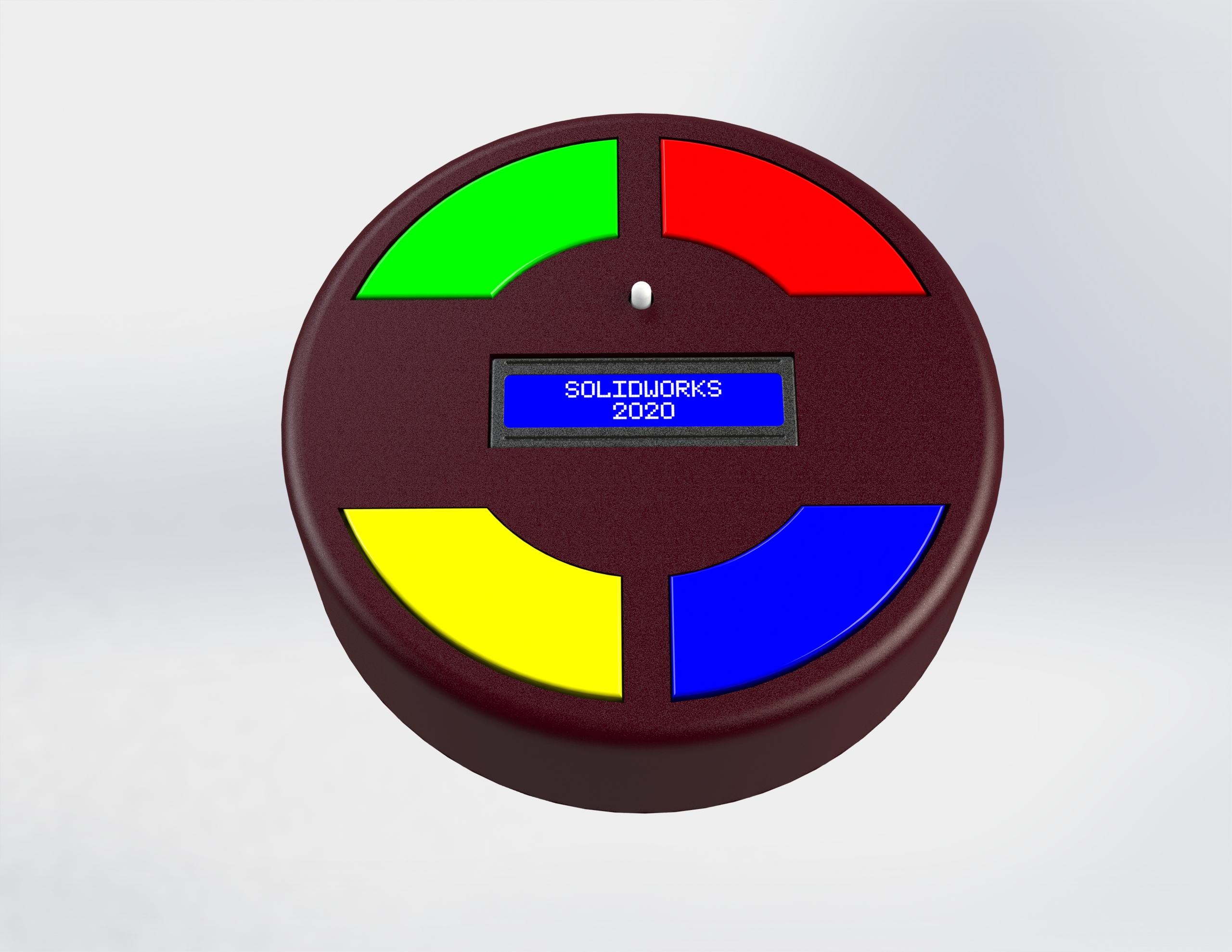

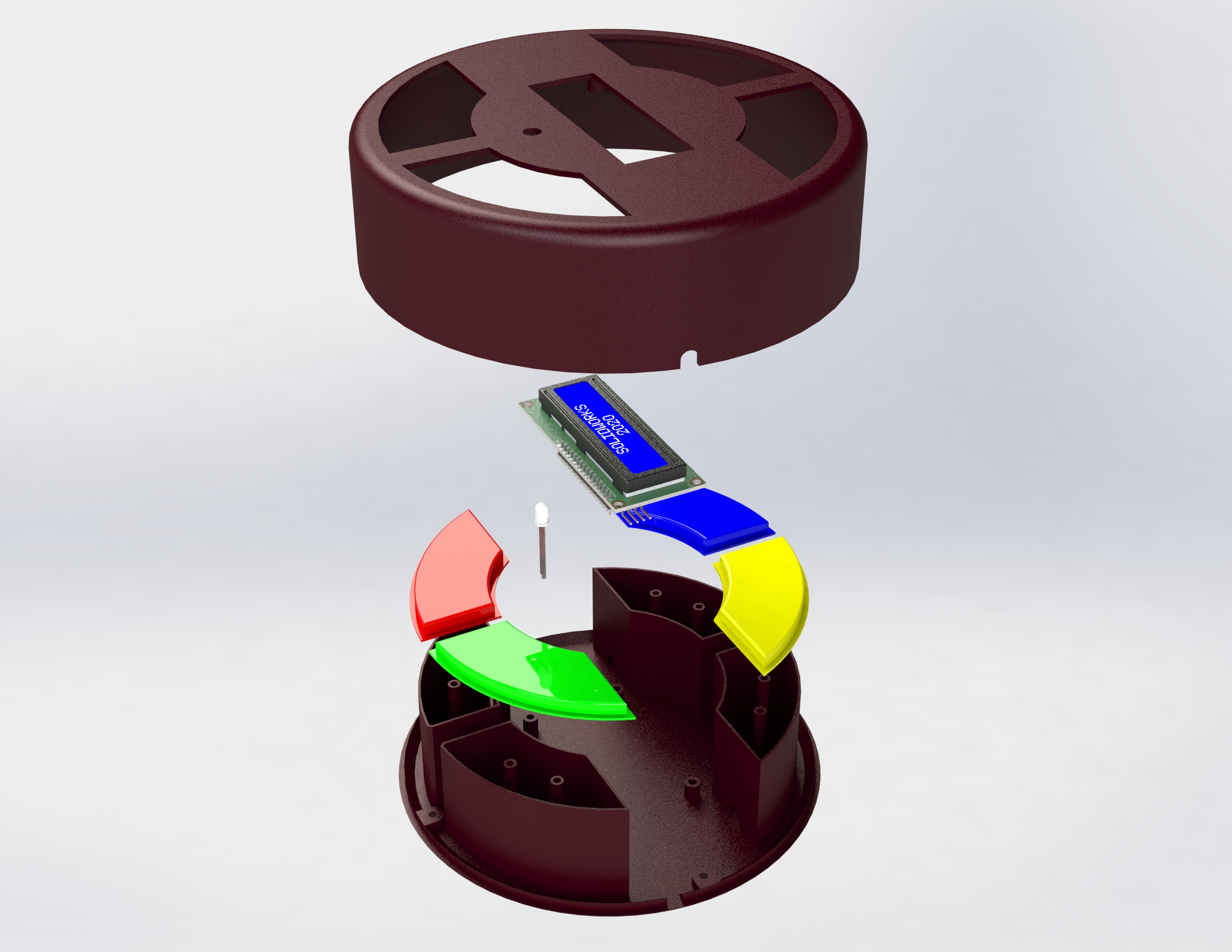

Task part 4 Design a 3D printed case

A 3D printed case was designed using the software SolidWorks 2021. The model is parametric, which make it easy to update by modifying some variables such as height, diameter, etc. The model is designed to be printed in a cartesian 3D printer, which creates some restrictions in the fabrication process, such as not printing in the air. This way, the simmons says prototype presented is made by 2 parts, the base and the top part, and then the 4 buttons. The microcontroller and the buttons will be attached to the basis, while the LCD and the RGB is on the top part. The 3D printed buttons are laying on the button PCB and surrounded by the top and the base parts, leaving only one degree of freedom to touch the button.

The different parts were printed in the Skylab laboratory. It took 15 hours in total, using the fastest settings with a low print quality. Since this was prototype, we used the fastest settings in order to save material.